Trending...

- Tacoma: FAQs on Proposed 0.1% Criminal Justice Sales & Use Tax

- T-TECH Partners with Japan USA Precision Tools for 2026 US Market Development of the New T-TECH 5-Axis QUICK MILL™

- UK Financial Ltd Announces A Special Board Meeting Today At 4PM: Orders MCAT Lock on CATEX, Adopts ERC-3643 Standard, & Cancels $0.20 MCOIN for $1

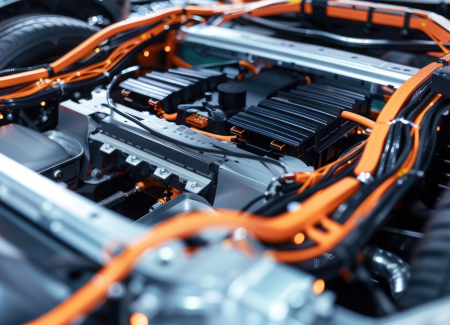

DALLAS, N.C. - Washingtoner -- Discover how one formulation enables cost-efficient, sustainable ESD packaging for the automotive industry without compromising performance.

Background

A leading German-based packaging manufacturer serving the automotive industry sought to enhance its offering of electrostatic discharge (ESD) safe polypropylene (PP) boxes used by major OEMs. The company had previously outsourced production but recently invested in its own production facility, signaling a strategic move toward expanding in-house manufacturing capacity to better serve its European customer base.

Challenge / Need

The customer was under significant cost pressure in a highly competitive market. The challenge was to meet strict ESD and mechanical performance targets while simultaneously reducing material costs and incorporating sustainable practices. The end customer—automotive OEMs—also demanded circularity and environmental compliance, adding complexity to material selection.

More on Washingtoner

Solution

Premix offered its conductive PRE-ELEC® compound, tailored for ESD packaging in the automotive sector. The standout feature was its ability to tolerate recycled content allowing integration of both generic and customer-specific regrind while maintaining key mechanical and conductive properties.

To verify this, dilution trials were conducted comparing the compound (0% additional regrind) with compound diluted by 10% of the customer's own regrind:

Surface Resistivity (Conductivity):

0% regrind: ~3.30E+04 Ω (excellent ESD performance)

10% regrind: 1.90E+05 Ω (still well within target conductivity range)

Impact Strength – Charpy Notched (ISO 179, +20 °C):

0% regrind: 58 kJ/m²

10% regrind: 54 kJ/m²

Impact Strength – Izod Notched (ISO 180, +20 °C):

0% regrind: 48 kJ/m²

10% regrind: 46 kJ/m²

These results demonstrated that PRE-ELEC® maintains its critical performance properties even with 10% regrind blended in—proving its robustness and suitability for circular economy applications.

More on Washingtoner

By enabling up to 40% (mentioned in our MSDS) regrind content in the compound and an additional 10% customer-specific regrind, Premix delivered a material solution that met both technical targets and cost efficiency goals for high-volume automotive packaging.

Results / Benefits

Cost Efficiency: The high regrind tolerance enabled significant material cost savings without compromising product quality.

Sustainability: By reusing internal waste and integrating recycled materials, the solution aligned with OEMs' sustainability goals.

Performance Assurance: Testing showed that the material retained key impact strengths despite the dilution with regrind.

The customer was highly satisfied, as Premix helped the packaging manufacturer remain competitive in a demanding market while advancing their transition toward a more circular production model.

Want to explore how Premix materials can support your packaging innovations? Contact us today at: https://www.premixgroup.com/premix-group/premix-in-the-us

Background

A leading German-based packaging manufacturer serving the automotive industry sought to enhance its offering of electrostatic discharge (ESD) safe polypropylene (PP) boxes used by major OEMs. The company had previously outsourced production but recently invested in its own production facility, signaling a strategic move toward expanding in-house manufacturing capacity to better serve its European customer base.

Challenge / Need

The customer was under significant cost pressure in a highly competitive market. The challenge was to meet strict ESD and mechanical performance targets while simultaneously reducing material costs and incorporating sustainable practices. The end customer—automotive OEMs—also demanded circularity and environmental compliance, adding complexity to material selection.

More on Washingtoner

- City of Tacoma Advances Vision Zero Goals with Updated Traffic Safety Program

- Tacoma: Transportation Impact Fees to Help Fund Critical Infrastructure and Enhance Safety

- Tacoma: A Statement from Mayor Victoria Woodards, At-Large Council Member Olgy Diaz, and District 4 Council Member Sandesh Sadalge on Resolution 41817

- City of Tacoma Deepens Cultural Ties with Croatia, Designates Split as New Sister City

- Tacoma City Council Designates Kochi, India as New Friendship City

Solution

Premix offered its conductive PRE-ELEC® compound, tailored for ESD packaging in the automotive sector. The standout feature was its ability to tolerate recycled content allowing integration of both generic and customer-specific regrind while maintaining key mechanical and conductive properties.

To verify this, dilution trials were conducted comparing the compound (0% additional regrind) with compound diluted by 10% of the customer's own regrind:

Surface Resistivity (Conductivity):

0% regrind: ~3.30E+04 Ω (excellent ESD performance)

10% regrind: 1.90E+05 Ω (still well within target conductivity range)

Impact Strength – Charpy Notched (ISO 179, +20 °C):

0% regrind: 58 kJ/m²

10% regrind: 54 kJ/m²

Impact Strength – Izod Notched (ISO 180, +20 °C):

0% regrind: 48 kJ/m²

10% regrind: 46 kJ/m²

These results demonstrated that PRE-ELEC® maintains its critical performance properties even with 10% regrind blended in—proving its robustness and suitability for circular economy applications.

More on Washingtoner

- Spokane: Welding Sparks Ignite Multi-Business Fire on Holyoke Avenue

- City Council Member Michael Cathcart Selected As Chair of Spokane Regional Health District Board of Health

- Naturism Resurgence (NRE) Announces the World's First Standardised Stigma Measure (SSM) for Naturism

- London Art Exchange Emerges as a Leading Force in UK Contemporary Art, Elevating Three Artists to Secondary-Market Success

- City of Spokane and City Council Announce 2026 Legislative Agenda

By enabling up to 40% (mentioned in our MSDS) regrind content in the compound and an additional 10% customer-specific regrind, Premix delivered a material solution that met both technical targets and cost efficiency goals for high-volume automotive packaging.

Results / Benefits

Cost Efficiency: The high regrind tolerance enabled significant material cost savings without compromising product quality.

Sustainability: By reusing internal waste and integrating recycled materials, the solution aligned with OEMs' sustainability goals.

Performance Assurance: Testing showed that the material retained key impact strengths despite the dilution with regrind.

The customer was highly satisfied, as Premix helped the packaging manufacturer remain competitive in a demanding market while advancing their transition toward a more circular production model.

Want to explore how Premix materials can support your packaging innovations? Contact us today at: https://www.premixgroup.com/premix-group/premix-in-the-us

Source: Premix

0 Comments

Latest on Washingtoner

- Tacoma: Homicide Investigation and Arrest– 6400 block of McKinley

- UK Financial Ltd Completes Full Ecosystem Conversion With Three New ERC-3643 SEC-Ready Tokens As MCAT Deadline Closes Tonight

- AI Real Estate Company Quietly Building a National Powerhouse: reAlpha Tech Corp. (N A S D A Q: AIRE)

- Inkdnylon Expands National Uniform Embroidery Services

- Appliance EMT Expands Appliance Repair Services to Portland, OR and Vancouver, WA

- Next Week: The World's Best Young Pianists Arrive in Music City for the 2025 Nashville International Chopin Piano Competition

- Revenue Optics Builds Out Its Dedicated Sales Recruiting Firm with Strategic Addition of Christine Schafer

- Hydrofast Elevates the Holiday Season: The C100 Countertop RO System Merges Smart Tech with Wellness for the Perfect Christmas Gift

- Melospeech Inc. Accepts Nomination for HealthTech Startup of the Year

- Flower City Tattoo Convention Draws Record Attendance in Rochester, NY

- New Chapbook Translates Truman's Ancient Playbook Into Practical Lessons for Modern Leaders

- KIKO NATION TOKEN (Official Release)

- Verb™ Presents Features Vanguard Personalized Indexing: Utilizing Advanced Tax-Loss Harvesting Technology

- Tacoma: FAQs on Proposed 0.1% Criminal Justice Sales & Use Tax

- UK Financial Ltd Announces A Special Board Meeting Today At 4PM: Orders MCAT Lock on CATEX, Adopts ERC-3643 Standard, & Cancels $0.20 MCOIN for $1

- Tacoma: City of Destiny Awards Nominations Accepted Now Through January 29, 2026

- Spokane: National Pearl Harbor Remembrance Day

- 6 Holiday Looks That Scream "Old Money" But Cost Less Than Your Christmas Tree

- FlintLab Announces Strategic Partnership with Genymotion

- From Cheer to Courtroom: The Hidden Legal Risks in Your Holiday Eggnog